Quality Assurance

- Home

-

Quality Assurance

Where Precision Meets Reliability

At Supermech Industries, quality isn’t just a checkpoint—it’s the foundation of everything we do. With over 20 years of experience in manufacturing, we’ve built a reputation for delivering durable, high-performance components that meet the highest industry standards.

Our Commitment to Quality

We follow a rigorous quality assurance process at every stage of production, from raw material selection to final inspection. Each product—whether it’s a B22 bulb holder ring, capacitor can, or V-belt pulley—is crafted with attention to detail and tested for performance, strength, and consistency.

Premium Materials

We use only high-grade raw materials, such as 99.8% pure aluminum for electrical parts and tested industrial alloys for transmission components, ensuring durability and long-term performance.

Compliance & Standards

Our manufacturing processes align with recognized industrial and safety standards to ensure reliability and customer satisfaction.

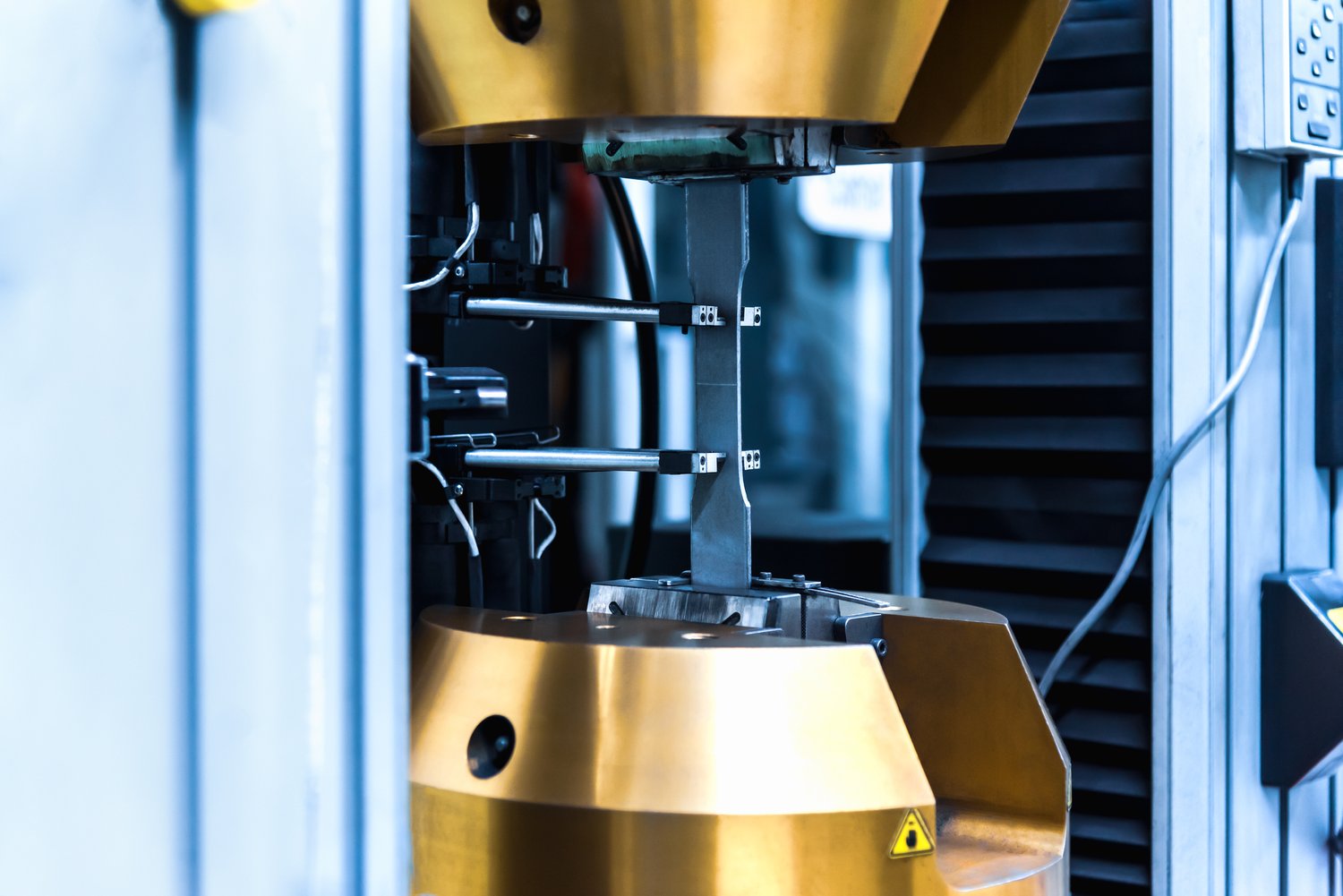

In-House Testing & Inspection

All products undergo dimensional accuracy checks, strength tests, and surface finish inspections. Our trained team ensures each batch meets technical specifications and client requirements.

Continuous Improvement

We invest in technology upgrades, staff training, and feedback-driven improvements to keep our quality management system strong and up-to-date.

https://supermechindustries.in/wp-content/uploads/2025/04/WhatsApp-Video-2025-04-23-at-16.35.31.mp4https://supermechindustries.in/wp-content/uploads/2025/04/WhatsApp-Video-2025-04-23-at-16.35.35.mp4https://supermechindustries.in/wp-content/uploads/2025/04/WhatsApp-Video-2025-04-23-at-16.35.38.mp4

Trusted by Clients Worldwide

From India to Abu Dhabi and South Africa, our clients trust Supermech Industries for parts that perform consistently under demanding industrial conditions. We believe in delivering not just products, but peace of mind.

Choose Supermech Industries – Where Quality is Engineered.

Certifications